- Courses

- GS Full Course 1 Year

- GS Full Course 2 Year

- GS Full Course 3 Year

- GS Full Course Till Selection

- Online Program

- GS Recorded Course

- NCERT (Recorded 500+ Hours)

- Polity Recorded Course

- Geography Recorded Course

- Economy Recorded Course

- AMAC Recorded Course

- Modern India, Post Independence & World History

- Environment Recoded Course

- Governance Recoded Course

- Science & Tech. Recoded Course

- International Relations and Internal Security Recorded Course

- Disaster Management Module Course

- Ethics Recoded Course

- Essay Recoded Course

- Current Affairs Recoded Course

- CSAT

- 5 LAYERED ARJUNA Mentorship

- Public Administration Optional

- ABOUT US

- OUR TOPPERS

- TEST SERIES

- FREE STUDY MATERIAL

- VIDEOS

- CONTACT US

CARBON FIBER: A REVOLUTIONARY MATERIAL

CARBON FIBER: A REVOLUTIONARY MATERIAL

06-04-2024

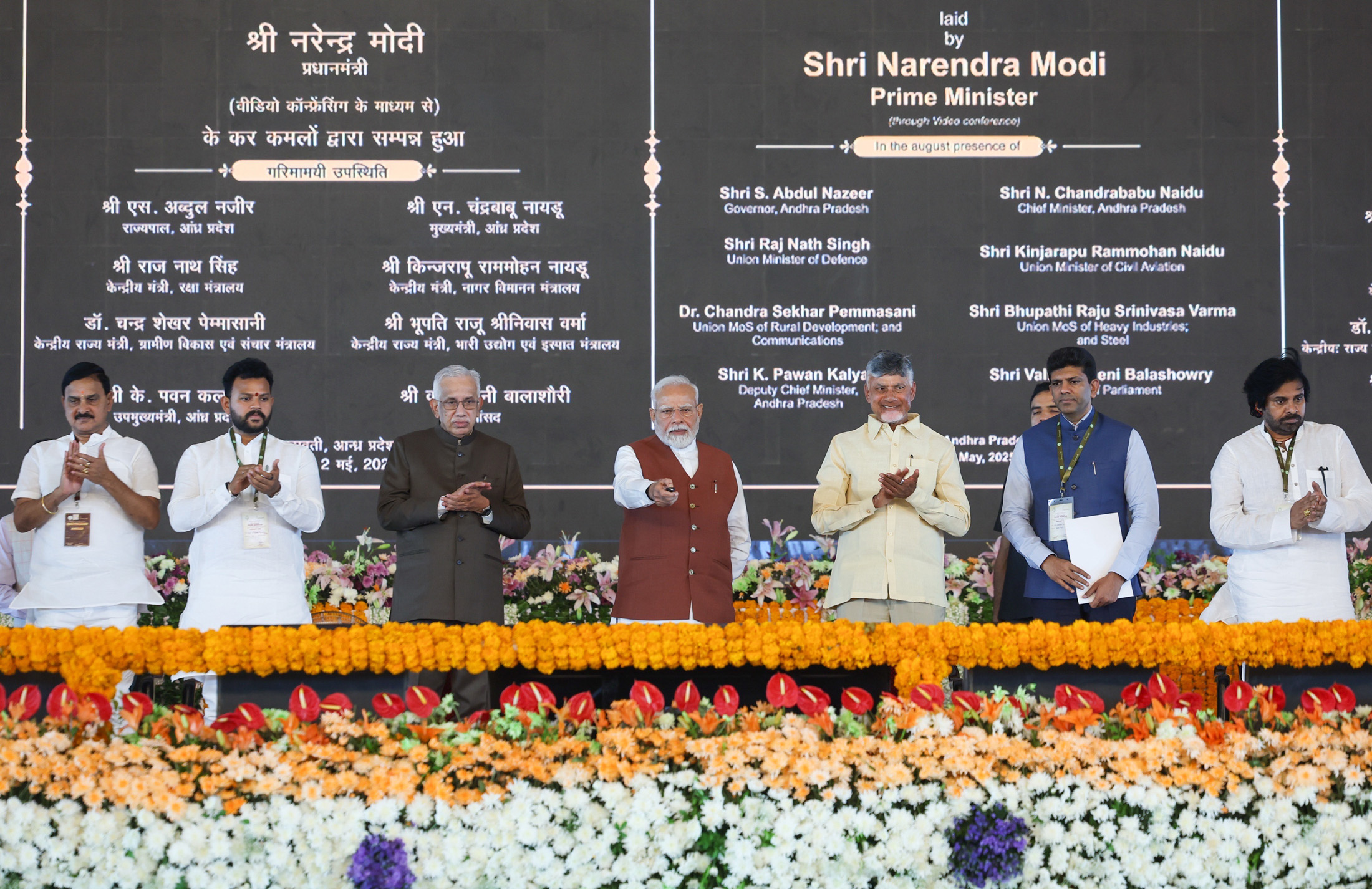

- India is focusing on manufacturing carbon fiber, a cutting-edge material with exceptional properties as an alternative to metal in the aerospace, civil engineering and defense sectors.

- This strategic move aims to address the potential impact of the proposed EU carbon tax on steel, alloy and metal products.

What is Carbon Fiber?

- Composition: Carbon fiber is made up of organic polymers, which are long chains of molecules held together by carbon atoms. Carbon fibers are 5–10 micrometers in diameter. About 90 percent of carbon fibres are made by using the polyacrylonitrile (PAN) process. The remaining 10 percent are made using either the rayon or petroleum pitch process.

- Properties:

- Strength: Carbon fiber is very strong and stiff, with a strength-to-weight ratio up to five times that of steel

- Weight: Carbon fiber is lightweight

- Thermal and electrical conductivity: Carbon fiber has good thermal and electrical conductivity

- Chemical resistance: Carbon fiber is resistant to chemicals

- Low CTE: Carbon fiber has a low coefficient of thermal expansion

- Corrosion resistance: Carbon fiber is resistant to corrosion

- X-ray transparency: Carbon fiber is transparent to X-rays

- Fatigue resistance: Carbon fiber is resistant to fatigue

- Creep resistance: Carbon fiber has excellent creep resistance

- Current Scenario: India currently lacks domestic production of carbon fiber, relying on imports from countries like the US, France, Japan and Germany.

- Applications:

- Essential for various applications, such as fighter aircraft noses, civilian aircraft, drone frames, car chassis, and fire-resistant building materials.

- India currently lacks domestic production of carbon fiber, relying only on imports from countries like the US, France, Japan and Germany.

FAQs:

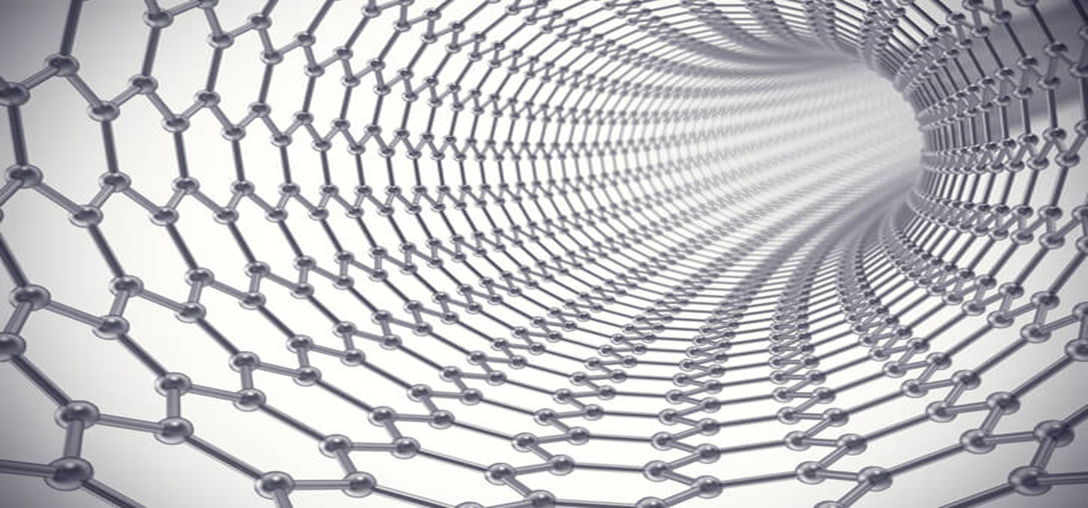

Q1: What are Carbon nanotubes (CNTs)?

Carbon nanotubes (CNTs) are nanometer-sized tubes made of carbon, and one of the allotropes of carbon. They are made by rolling up graphene sheets into a seamless cylinder. CNTs have a wide range of applications in science, engineering, and the environment

CNTs have remarkable properties, including:

- Strength: CNTs are extremely robust and difficult to break, but they are still light.

- Thermal conductivity: CNTs have exceptional thermal conductivity.

- Electrical conductivity: Some SWCNT structures exhibit high electrical conductivity while others are semiconductors.

- Mechanical strength: CNTs have a high mechanical strength.

Carbon nanotubes (CNTs) have many applications in nanotechnology and nanoscience. Some applications include:

- Biomedical: Drug delivery, cancer treatment, tissue engineering, wound healing, biosensors, and imaging

- Fuel cells: Electrode catalyst supports, gas diffusion layers, and current collectors

- Aerospace: Aircraft and spacecraft bodies

- Electronics: Thin-film transistors, conductive latex gloves, and conductive ink

- Transportation: Bullet-proof jackets, vehicle manufacturing, and carbon-fiber bicycle parts

- Satellites: Thruster field emitting property

- Antennas: Radios and other electromagnetic devices

Must Check: Best IAS Coaching In Delhi