- Courses

- GS Full Course 1 Year

- GS Full Course 2 Year

- GS Full Course 3 Year

- GS Full Course Till Selection

- CSAT

- 5 LAYERED ARJUNA Mentorship

- Public Administration Optional

- Online Program

- GS Recorded Course

- NCERT (Recorded 500+ Hours)

- Polity Recorded Course

- Geography Recorded Course

- Economy Recorded Course

- AMAC Recorded Course

- Modern India, Post Independence & World History

- Environment Recoded Course

- Governance Recoded Course

- Science & Tech. Recoded Course

- International Relations and Internal Security Recorded Course

- Disaster Management Module Course

- Ethics Recoded Course

- Essay Recoded Course

- Current Affairs Recoded Course

- ABOUT US

- OUR TOPPERS

- TEST SERIES

- FREE STUDY MATERIAL

- VIDEOS

- CONTACT US

Revised Good Manufacturing Practices

Revised Good Manufacturing Practices

-1691585850020.png)

Latest Context:

Recently, the Indian government ordered all pharmaceutical companies to implement the revised Good Manufacturing Practices (GMP), bringing their processes at par with international standards.

What are Good Manufacturing Practices (GMP)?

-

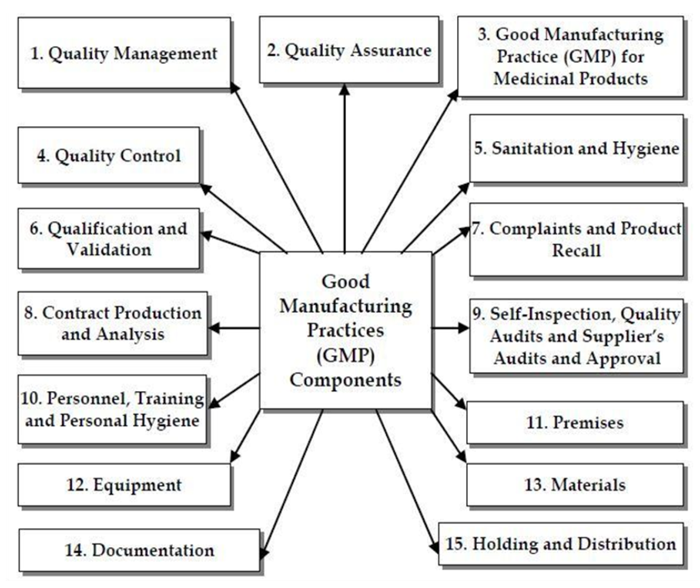

GMP are a set of guidelines and regulations that ensure the consistent production of high-quality and safe products in various industries, especially those involving pharmaceuticals, food, cosmetics, and medical devices.

-

GMP guidelines are designed to ensure that products are manufactured, processed, tested, and packaged in a controlled and standardized manner to minimize the risk of contamination, errors, and deviations that could impact the quality, safety and efficacy of the final product.

-

WHO has established detailed guidelines for GMP and many countries of the world have formulated their own GMP based on WHO GMP.

Major changes in revised GMP guidelines are:

-

Basically, the new guidelines introduced a provision of “pharmaceutical quality system”, which focuses on the establishment of a comprehensive quality management system throughout the manufacturing process.

-

Now, companies should implement quality risk management practices to identify potential risks to the quality of their products and to take appropriate steps in this direction.

-

Regular quality reviews of all products are mandated by the guidelines to ensure consistency in quality and processes.

-

These guidelines focus on the use of computerized systems to handle GMP-related processes.

-

The products used in clinical trials should meet the necessary quality and safety standards.

What is the need of revised GMP Guidelines?

-

Implementation of these new guidelines will bring the Indian industry at par with the international standards.

-

Many incidents have been reported, where other countries have reported contamination in Indian syrups, eye-drops etc.

-

A recent inspection found high deficiencies in almost 162 manufacturing units in India.

-

At present, only 2,000 out of 10,500 drug manufacturing units in India meet global standards. So, the improved standards will ensure that pharmaceutical companies should follow standard processes and quality control measures.

-

Same quality across the industry will provide confidence to regulators from other countries.

Conclusion and Way Forward

-

India's decision to implement revised GMP guidelines shows a big step towards achieving global quality standards in the pharmaceutical industry.

-

Following the revised GMP guidelines helps companies ensure the safety, quality, and efficacy of their products, while minimizing the risks associated with manufacturing processes.

Must Check: IAS Coaching Centre In Delhi