- Courses

- GS Full Course 1 Year

- GS Full Course 2 Year

- GS Full Course 3 Year

- GS Full Course Till Selection

- Online Program

- GS Recorded Course

- NCERT (Recorded 500+ Hours)

- Polity Recorded Course

- Geography Recorded Course

- Economy Recorded Course

- AMAC Recorded Course

- Modern India, Post Independence & World History

- Environment Recoded Course

- Governance Recoded Course

- Science & Tech. Recoded Course

- International Relations and Internal Security Recorded Course

- Disaster Management Module Course

- Ethics Recoded Course

- Essay Recoded Course

- Current Affairs Recoded Course

- CSAT

- 5 LAYERED ARJUNA Mentorship

- Public Administration Optional

- ABOUT US

- OUR TOPPERS

- TEST SERIES

- FREE STUDY MATERIAL

- VIDEOS

- CONTACT US

Biomass Co-Firing In Thermal Power Plants

Biomass Co-Firing In Thermal Power Plants

Why in News?

Recently, issue of limited biomass co-firing by thermal plats has again been highlighted as Delhi’s AQI is in “very poor’ category and Only three plants have reported higher quantities of biomass co-firing since December 2022 till August 2023.

- The Centre for Science and Environment conducted a 2022 survey to assess the progress of policy implementation on co-firing biomass in coal-fired thermal power plants in the National Capital Region.

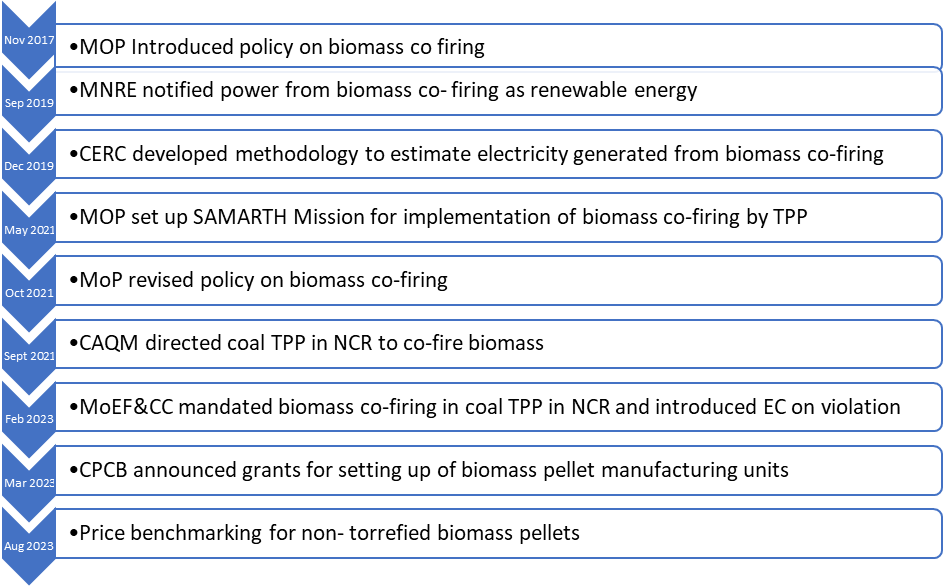

Chronology of Developments

Highlights of the Survey Conducted by CSE

-

Reasons for Delay in Biomass Co-Firing Implementation: CSE investigated the reasons behind the delay in implementing the mandated 5% co-firing by coal thermal power plants (TPP) in the NCR and surrounding areas.

-

Weak Supply Chain: The Harduaganj Thermal Power Plant credits its success in co-firing biomass to a consistent and affordable supply, but acknowledges the need for further strengthening of the supply chain.

-

Technical Limitations: Haryana Power Generation Corporation Limited (HPGCL) is grappling with technical challenges and a shortage of skilled biomass pellet manufacturers.

-

Lack of investments: Mahatma Gandhi Thermal Power Plant highlighted need for significant investments to increase biomass co-firing to the mandated level.

-

Limited Vendors: Talwandi Saboo TPP faced difficulties in locating vendors for its plant due to the lack of established technology for producing torrefied biomass pellets.

-

Challenges in Implementing Biomass Co-Firing for Farm Fire Reduction:

-

The study indicates that despite government directives and efforts to improve pellet manufacturing capacity, biomass co-firing may not significantly reduce farm fires.

-

To effectively tackle stubble burning, a coordinated approach involving timely planning by coal TPPs and crop residue procurement by pellet manufacturers is crucial.

-

Around 95,000-96,000 tonnes of biomass pellets are required per day for co-firing, However, its manufacturing capacity is 7,000 tonnes per day at present despite a surplus 228 million tonnes of agricultural residue available in the country.

-

Long-term storage of biomass pellets at plant sites is challenging due to their rapid absorption of air moisture, making them unsuitable for co-firing.

-

The significant gap in biomass pellet supply to the utility is primarily due to seasonal availability and unreliable supply.

What is Biomass Co-Firing?

-

Definition: Biomass co-firing is the process of replacing a portion of the fuel with biomass in coal thermal plants.

-

About:

-

Coal and biomass are combined in boilers specifically designed for burning coal. The existing coal power plant needs to be partially reconstructed and retrofitted for this purpose.

-

Co-firing is a sustainable and efficient method for converting biomass into electricity, thereby reducing greenhouse gas emissions from power plants.

-

Biomass co-firing is a widely recognized and cost-effective method for decarbonizing a coal fleet globally.

-

The Finance Minister stated in 2022's budget speech that co-firing 5 to 7% biomass pellets in thermal power plants can prevent 38 million tonnes of carbon dioxide annually.

Sources of Biomass

-

Ministry of Power has identified various surplus agro residues that can be utilized for biomass pellet production. These include:

-

Crop Residues: Agro-residues from various crops like Paddy, Soya, Arhar, Gwar, Cotton, Gram, Jawar, Bajra, Moong, Mustard, Sesame, Til, Maize, Sunflower, Jute, and Coffee are used in various industries.

-

Shell Waste: Waste products such as Groundnut Shell, Coconut Shell, and Castor Seed Shell are considered waste.

-

Additional Sources:

-

Bamboo, by-products, horticulture waste, and other biomass materials like Pine Cone/Needle, Elephant Grass, and Sarkanda are all valuable resources.

Measures taken to promote Biomass Co-firing

-

Ministry of Environment and Forestry (MNRE) and the Central Pollution Control Board (CPCB) have introduced Finance Assistance Schemes to support biomass pellet manufacturing units.

-

The Reserve Bank of India has approved biomass pellet manufacturing as an eligible activity under Priority Sector Lending, ensuring financial viability for such endeavors.

-

Government e-Marketplace (GeM) portal has been launched as a dedicated Procurement Provision for the Biomass Category.

-

Ministry of Power has introduced a Revised Model Long-Term Contract for Biomass Supply to ensure a consistent supply chain.

-

The implementation of Udyam Aadhaar on the National Single Window System has been deemed effective in streamlining administrative procedures for biomass-related projects.

-

National Mission on use of Biomass in Coal Based Thermal Power Plants has been implemented to promote use of biomass in Thermal power plants.

Way Forward

-

Ensuring a Steady Supply of Biomass to Power Plants

-

A reliable supply chain can ensure the steady supply of biomass to power plants by transporting it from source to plant.

-

This could involve collaborating with farmers, forestry companies, or other biomass suppliers to ensure a consistent supply of biomass.

-

Building Infrastructure and Logistics:

-

The success of biomass co-firing relies heavily on the development of the necessary infrastructure and logistics for transporting, storing, and processing biomass.

-

The proposed solution could involve the construction of new storage facilities, the enhancement of transportation networks, or the investment in advanced processing technologies.

-

Robust Regulatory Framework:

-

The Biomass Co-firing Policy requires a robust policy and regulatory framework that offers incentives and support for biomass co-firing.

-

The project involves creating specialized boilers, burners, and control systems for biomass co-firing, as well as retrofitting existing equipment.

Conclusion

The Indian government is enhancing the capacity of pellet manufacturers through training programs and requiring them to register under SAMARTH to strengthen the supply chain.